Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork.

Disadvantages of sheet metal working.

Roll forming this process is for long parts with constant complex cross sections.

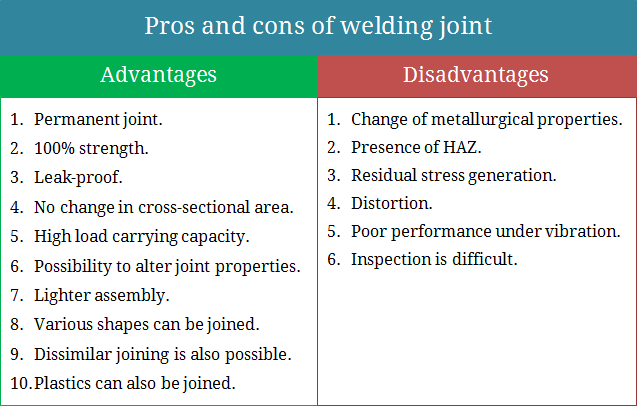

This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.

Sheet metal is one of the most versatile and widely used construction materials with applications in just about every industry imaginable from mining construction farming catering hospitality shipping manufacturing aviation medical and transport.

Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more.

There are several processes involved such as the stretch forming.

Top benefits of using sheet metal in construction 25 april 2015.

The unique properties of sheet metal make it a rather dangerous material to handle.

Pros of sheet metal roofing.

But sheet metal isn t only used in industrial situations we find it.

There is no blanket rule in deciding whether or not a particular sheet metal stamping design is perfect or there are certain disadvantages to it.

If your company produces transports or handles sheet metal you should take additional precautions to ensure the safety of your employees.

Every requirement in an industrial setup is unique and there are lots of factors that need to be considering when deciding whether or not a particular process is beneficial or not.

Some companies completely overlook sheet metal as a potential workplace hazard leaving employees susceptible to work related accidents.

We are here to break down the advantages and disadvantages of sheet metal roofing from characteristics to the installation process as well as maintenance tips.

Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more.

When working with sheet metal be certain that the base material is always the same.

Metal is more cost efficient when it comes to long term high volume lines of production.

Read on to find the pros and cons of sheet metal roofing.

Metal can go through a wider range of processes including chipping deep drawing casting forging welding and soldering.

Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal.